- 1. How is rugged hardware built differently?

- 2. Why is rugged hardware important?

- 3. What types of rugged hardware exist?

- 4. What are the benefits of rugged hardware?

- 5. Which industries rely most on rugged hardware?

- 6. Which standards define rugged hardware?

- 7. How is rugged hardware tested?

- 8. How does rugged hardware fit into network security?

- 9. Rugged hardware FAQs

- How is rugged hardware built differently?

- Why is rugged hardware important?

- What types of rugged hardware exist?

- What are the benefits of rugged hardware?

- Which industries rely most on rugged hardware?

- Which standards define rugged hardware?

- How is rugged hardware tested?

- How does rugged hardware fit into network security?

- Rugged hardware FAQs

What Is Rugged Hardware? An Overview

- How is rugged hardware built differently?

- Why is rugged hardware important?

- What types of rugged hardware exist?

- What are the benefits of rugged hardware?

- Which industries rely most on rugged hardware?

- Which standards define rugged hardware?

- How is rugged hardware tested?

- How does rugged hardware fit into network security?

- Rugged hardware FAQs

Rugged hardware is computing or networking equipment designed to operate reliably in harsh environmental conditions such as extreme temperatures, dust, moisture, vibration, and shock. It's built with reinforced materials, sealed enclosures, and specialized components that meet standards like MIL-STD-810H, IEC 60529, or NEMA 250.

Rugged hardware, also referred to as ruggedized hardware, is used in industrial, military, and remote settings where conventional devices cannot maintain performance or durability.

How is rugged hardware built differently?

Rugged hardware differs from standard equipment because it's engineered to survive environmental stress.

Devices are constructed with reinforced enclosures, shock-absorbing mounts, and materials that tolerate wide temperature swings. Seals and gaskets block dust and water, helping hardware meet ingress protection levels.

Internal components are also adapted.

Thermal design allows electronics to keep working in extreme heat or cold. Connectors and interfaces are strengthened to resist vibration and repeated use in field conditions. Power systems may include fail-safe features, such as pass-through operation during outages, to keep connectivity available.

Important: Ruggedization doesn't change what the device does.

It changes how reliably it can do it under stress. That's why standards like MIL-STD-810H and DO-160 focus on testing durability against shock, altitude, and environmental exposure. The result is hardware built not just for performance, but for continuity when conditions are harsh.

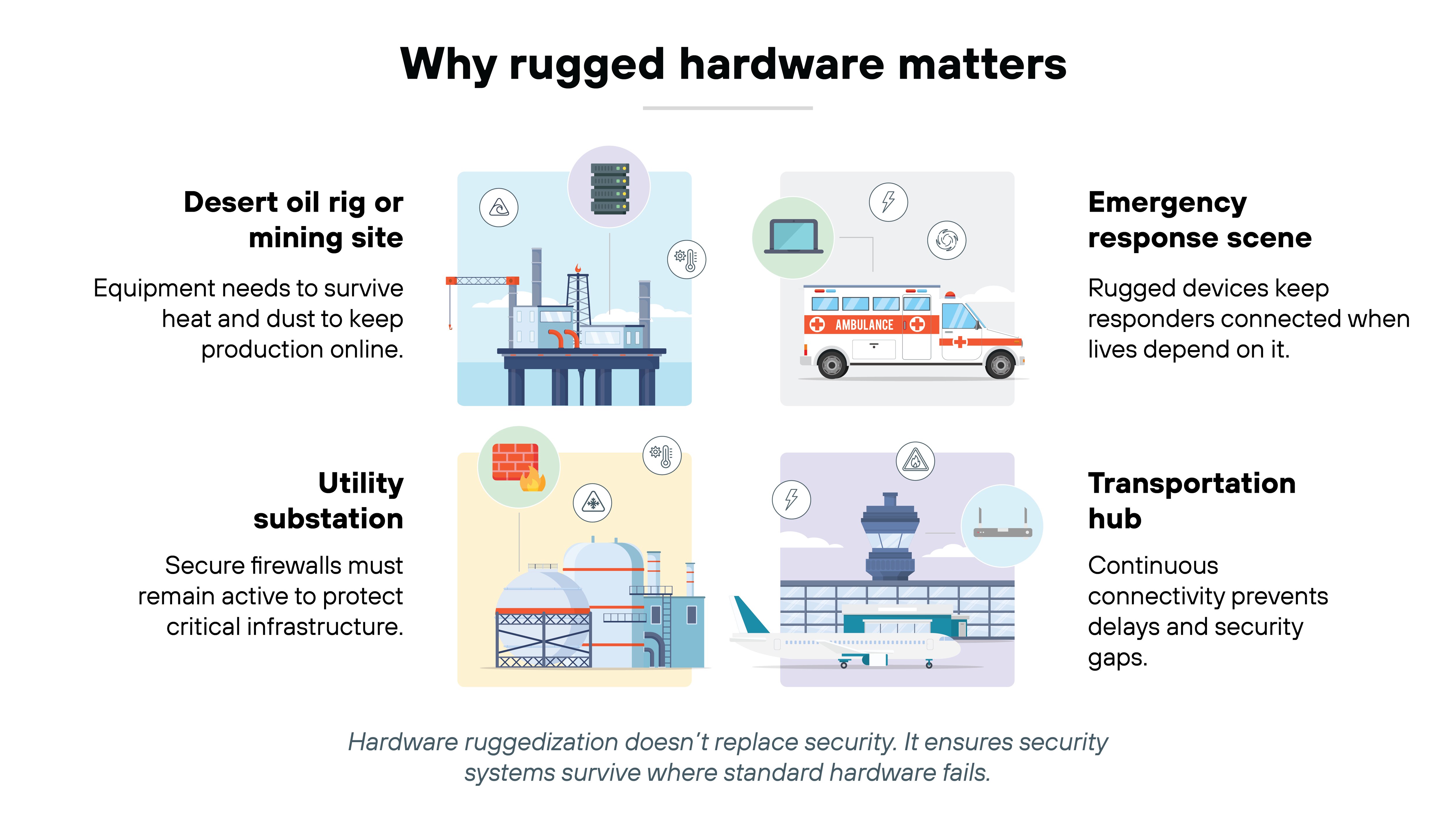

Why is rugged hardware important?

Rugged hardware is important because it allows critical systems to keep working in places where standard equipment would fail.

Harsh environments put stress on devices through heat, cold, dust, water, and vibration. Without reinforcement, most conventional equipment stops functioning reliably under those conditions.

In other words: Ruggedization exists to ensure business continuity and mission success when conditions aren't predictable.

Think about remote industrial sites, substations, or emergency response scenarios.

Equipment there can't shut down every time the temperature spikes or the power supply fluctuates. Rugged devices are designed to keep running, which means operations aren't disrupted and safety risks are reduced.

Here's why this matters for organizations.

Failures in the field don't just cause downtime. They delay work, increase maintenance costs, and can create security gaps. Ruggedized hardware reduces that risk by being built for durability from the start.

It's worth noting: Ruggedization doesn't replace security. It ensures the hardware can survive so security functions like firewalls and network controls remain active.

That's why rugged hardware is a foundation for reliable operations in industrial, remote, and mission-critical environments.

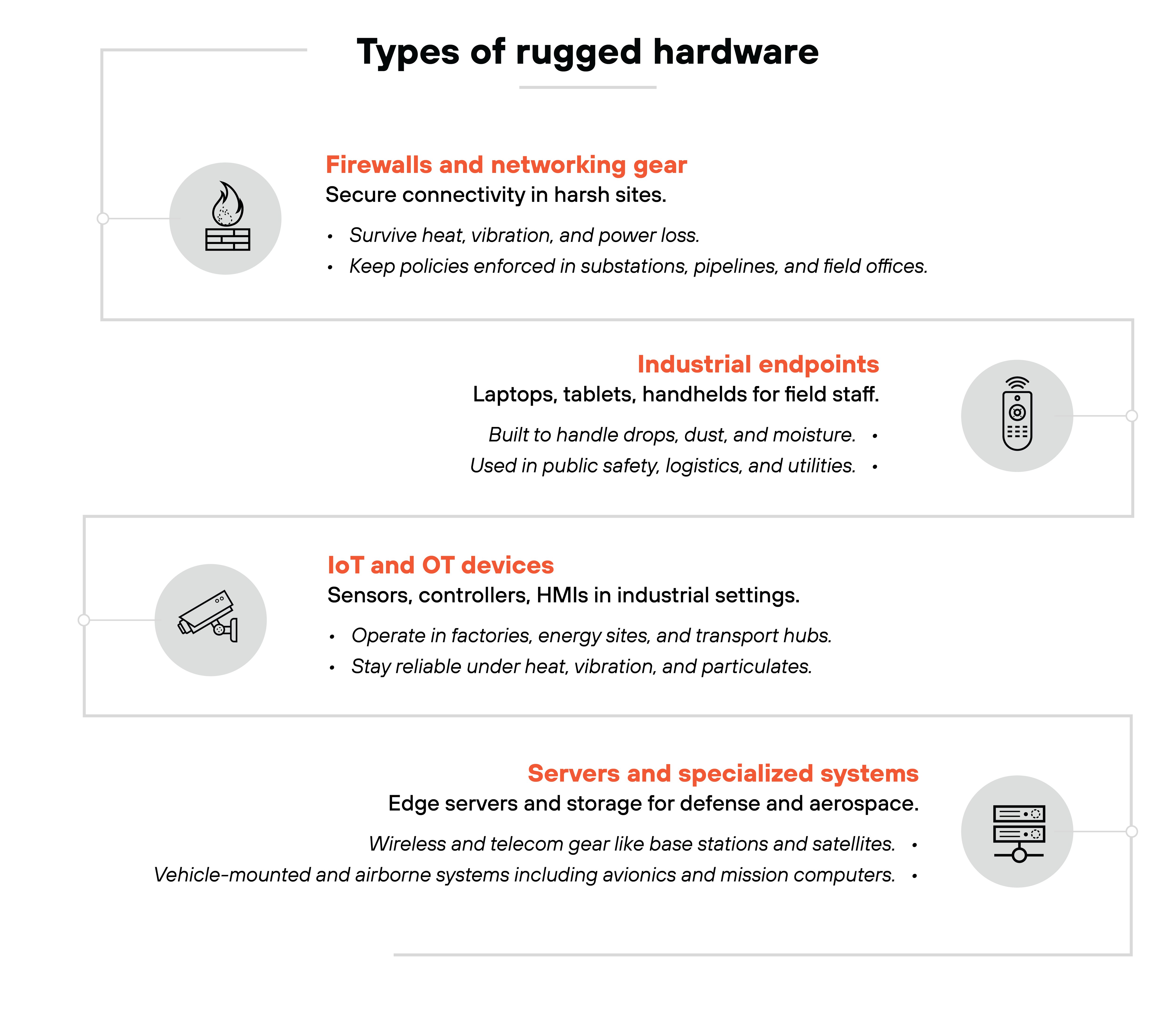

What types of rugged hardware exist?

Rugged hardware comes in several forms depending on the role it plays in the environment.

Some devices secure networks. Others support field staff or run industrial processes. A smaller set of specialized systems extend compute and connectivity into the most demanding locations.

Let's dive into a brief overview of each.

Firewalls and networking gear

Rugged firewalls and networking appliances are built for secure connectivity in harsh or remote environments. They protect networks from threats while tolerating wide temperature ranges, vibration, and unreliable power.

For instance, ruggedized next-generation firewalls can continue enforcing policies in substations, pipelines, or field offices where standard hardware would fail.

Industrial endpoints

These include laptops, tablets, and handheld computers that field staff use for data collection and communication.

They're designed to handle drops, moisture, and exposure to dust. Industrial endpoints are common in public safety, logistics, and utilities, where employees need reliable tools that can travel with them into demanding conditions.

IoT and OT devices

Ruggedized IoT and OT devices include sensors, controllers, and human-machine interfaces used in industrial settings.

They operate in factories, energy sites, and transportation hubs where heat, vibration, or particulate matter would damage conventional electronics. Ruggedization makes sure these devices can keep providing real-time data and process control.

Servers and specialized systems

Some environments require more complex rugged system, like:

- Servers and storage appliances deployed at the edge, such as in defense or aerospace

- Rugged wireless and telecom gear like base stations and satellite terminals that must survive outdoors

- Vehicle-mounted or airborne systems, like avionics or mission computers

Each serves niche but critical roles where environmental stress is unavoidable.

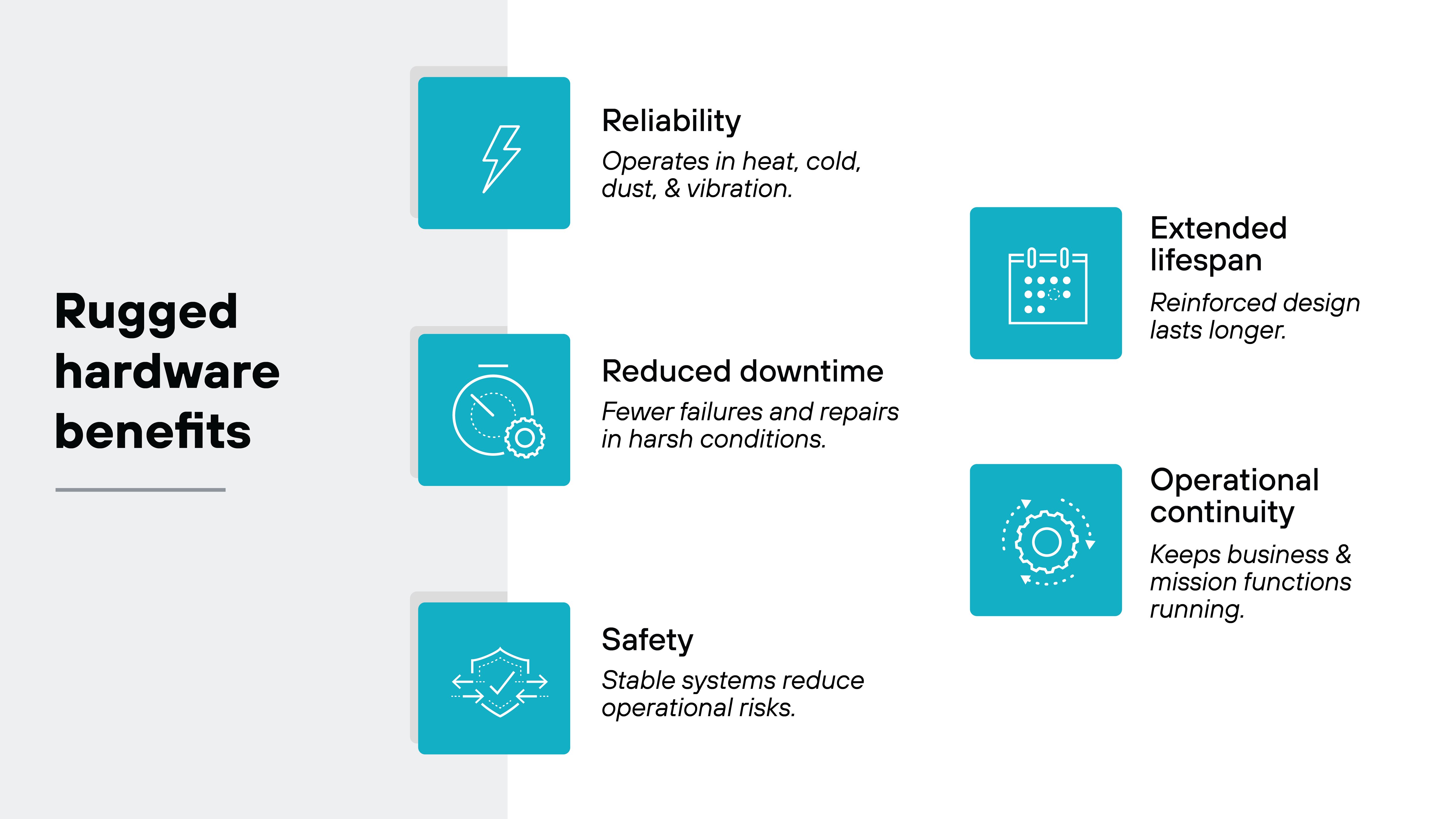

What are the benefits of rugged hardware?

The main benefit of rugged hardware is reliability. Devices keep working even when exposed to heat, cold, dust, or vibration. Which means critical operations can continue without interruption.

Another advantage is reduced downtime. Standard equipment often fails when pushed outside controlled conditions. Rugged hardware is built to avoid those failures, so organizations spend less time and money on replacements or repairs.

Safety is another factor. When hardware runs consistently, operators can depend on the systems that support industrial processes, emergency response, or field communication. Failures in these areas can create unnecessary risks.

Rugged hardware also extends the usable lifespan of devices. Reinforced materials and specialized designs mean they can withstand wear that would quickly degrade conventional equipment.

The bottom line: All of these benefits combine into operational continuity. Rugged hardware helps organizations maintain business and mission functions even when conditions are far from ideal.

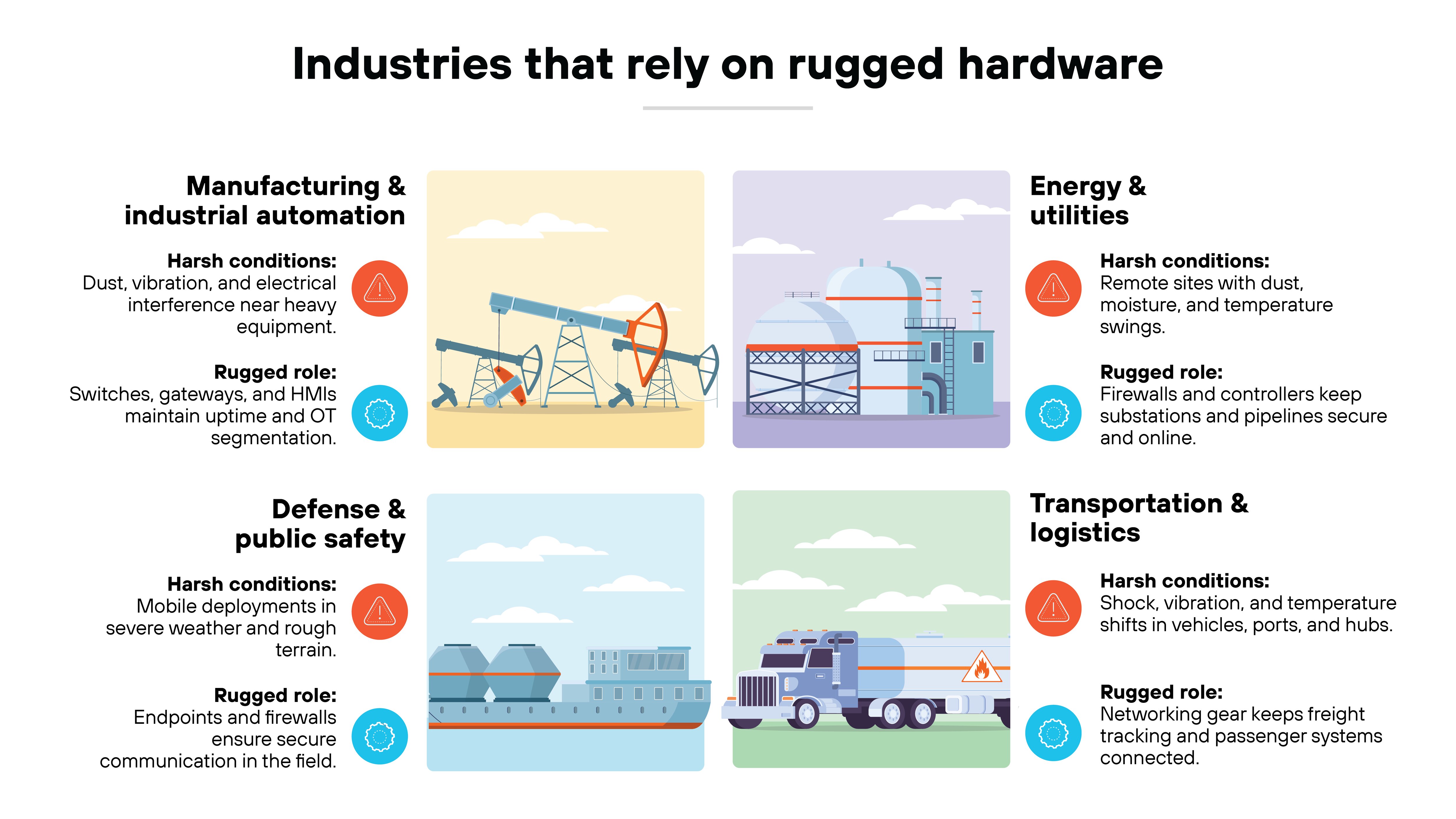

Which industries rely most on rugged hardware?

Rugged hardware is essential in industries where operations are exposed to demanding environments and downtime creates real consequences.

These are the sectors where equipment has to survive stress that conventional systems cannot handle.

Energy and utilities

Energy and utility operations take place in substations, drilling sites, and distribution networks that face constant exposure to environmental stress. Dust, vibration, extreme heat, or freezing conditions can all disrupt hardware that isn't designed for the task. If systems fail, the result can be interrupted service and increased safety risks.

- Harsh conditions: Remote sites with dust, moisture, vibration, and wide temperature swings,

- Why it matters: Outages can interrupt generation or service and raise safety and compliance risk.

- Rugged hardware role: Ruggedized firewalls, routers, and controllers keep connectivity and control online at substations and extraction sites.

Manufacturing and industrial automation

Factories and process plants operate in environments filled with dust, continuous vibration, and electromagnetic interference. Hardware here must run close to heavy equipment while tolerating temperature changes and electrical noise. If failures occur, production slows or stops, which directly affects quality and efficiency.

- Harsh conditions: Persistent dust, continuous vibration, electromagnetic interference, and thermal variation.

- Why it matters: Interruptions degrade product quality and reduce throughput on the line.

- Rugged hardware role: Hardened switches, gateways, HMIs, and security appliances sustain operations and support segmentation in OT zones.

Transportation and logistics

Transportation and logistics networks cover rail, air, maritime, and trucking systems. Hardware in these areas is exposed to vibration, shock, and fluctuating temperatures, whether mounted in vehicles or deployed in ports and warehouses. Failures can cause missed schedules and, in passenger systems, affect safety.

- Harsh conditions: Shock, vibration, and temperature swings across vehicles, rail yards, ports, and warehouses.

- Why it matters: Connectivity failures disrupt supply chains and can affect passenger safety.

- Rugged hardware role: Resilient networking and policy enforcement on moving assets and at hubs maintain telemetry, tracking, and secure data flow.

Defense and public safety

Defense and public safety operations often depend on equipment that works in mobile, unpredictable conditions. Field deployments may involve severe weather, rough terrain, and rapidly changing requirements. Rugged hardware ensures critical systems keep working when response or mission success depends on reliable communication.

- Harsh conditions: Field deployments, mobile command posts, and weather extremes.

- Why it matters: Mission readiness and response depend on equipment that works anywhere.

- Rugged hardware role: Rugged endpoints and secure appliances enable reliable communications and data exchange during operations.

Which standards define rugged hardware?

Rugged hardware is measured against established standards that describe how devices perform under environmental stress.

Each standard has its own scope, strengths, and limitations. In other words: no single test defines ruggedization.

The table below explains the most widely used references.

| Standards that define rugged hardware |

|---|

| Standard | What it covers | Scope and use | Limitations |

|---|---|---|---|

| MIL-STD-810H | Environmental test methods for vibration, shock, temperature extremes, humidity, sand, dust, and more. | Published by the U.S. Department of Defense. Widely used by defense, industrial, and commercial vendors as proof of resilience. | Not a centralized certification. Compliance claims vary depending on which methods were tested and how they were applied. |

| IEC 60529 (IP ratings) | Ingress protection against solids and liquids, expressed in two digits (e.g., IP67, IP68). | Used internationally to classify how well enclosures block dust and water. Common across consumer, industrial, and networking equipment. | Only addresses ingress protection. Doesn't cover vibration, shock, or thermal stress. |

| ANSI/NEMA 250 | Enclosure ratings for electrical equipment up to 1000 volts. Includes corrosion, dust, oil, and water exposure. | Used mainly in North America for industrial equipment, utilities, and fixed enclosures. Offers broader coverage than IP codes in certain areas. | Doesn't cover every environmental hazard. Specific to enclosures rather than overall device performance. |

| RTCA DO-160 | Environmental conditions for airborne equipment, including temperature, vibration, altitude, RF emissions, and lightning effects. | Developed for aviation. Applied to avionics, mission computers, and airborne communication systems. | Focused on aerospace. Less relevant for industrial or ground-based rugged equipment. |

| Other industry-specific standards | Regional or sector-focused guidelines such as DEF STAN 00-35, NATO AECTP-100, IEEE 1613 / IEC 61850-3, UL 50 / UL 50E, ATEX (a regulatory directive), IECEx, and SAE J1455. | Applied in defense, energy, transportation, or hazardous industries where specialized conditions apply. | Not universal. Applicability is limited to specific regions, sectors, or equipment types. |

How is rugged hardware tested?

Rugged hardware is tested against environmental conditions that mirror the stresses of real deployments. Testing isn't about proving a device is indestructible. It's about showing how well it performs when exposed to factors like heat, cold, water, or vibration.

One of the best-known frameworks is MIL-STD-810H. It includes methods for shock, vibration, altitude, humidity, and temperature extremes. The standard is flexible. Which means vendors can tailor the tests that apply to their product and operating environment. However, there's no central certification process, so claims should be reviewed carefully.

Ingress protection testing, defined by IEC 60529, evaluates how enclosures resist dust and water. A two-digit IP rating communicates the level of protection. For example, IP67 means dust-tight and able to withstand short immersion in water.

NEMA enclosure ratings cover similar ground but add conditions like corrosion, oil, and icing. These are often applied in North American industrial settings. In aerospace, DO-160 defines environmental tests for avionics and airborne systems, including exposure to pressure changes, vibration, and lightning.

Here's the takeaway: Each standard measures specific factors. Together they create a framework, but no single test captures every condition rugged hardware may face.

How does rugged hardware fit into network security?

Network security depends on reliable enforcement points.

Firewalls, gateways, and other appliances have to inspect traffic, enforce segmentation, and apply policies at every location where networks connect. If those devices go down, the security controls go with them.

And that's why rugged hardware matters.

As explained, standard appliances can fail when exposed to vibration, extreme temperatures, or unstable power. Ruggedized hardware, however, is designed to survive those conditions. Which means the network security functions built into the device remain available in places where conventional gear wouldn't last.

Ruggedized firewalls are a great example.

They extend the security perimeter into substations, remote offices, transportation hubs, and field sites. By tolerating environmental stress, they keep essential protections like intrusion prevention, traffic filtering, and zero trust policy enforcement active.

Remember: Ruggedization doesn't add new types of security.

It ensures existing network defenses operate consistently across harsh or remote deployments. That reliability helps organizations maintain secure connectivity everywhere the network reaches.